MIL-DTL-28837C

4.7 Methods of examination and test.

4.7.1 Visual and mechanical examination. Mixers shall be examined to verify that the material, design,

construction, physical dimensions, marking, and workmanship are in accordance with the applicable requirements

4.7.2 Preconditioning (screened only) (see 3.5). Unless otherwise specified, all screened mixers shall be

preconditioned by subjecting them to the maximum operating temperature (see 3.1), for a 24 hour period.

Subsequently each mixer shall meet the requirements of table III in the order shown.

4.7.3 Burn-in (screened only) (see 3.6). All screened mixers shall be tested by applying a 30 mA dc, unless

otherwise specified (see 3.1) to the IF port for 48 hours in each polarity. Each mixer shall meet the requirements of

table III in the order shown.

4.7.4 Electrical characteristics (see 3.7). The electrical characteristics shall be determined by the tests specified

herein, as applicable (see 3.1). Electrical tests included herein do not embrace all of the electrical tests that may be

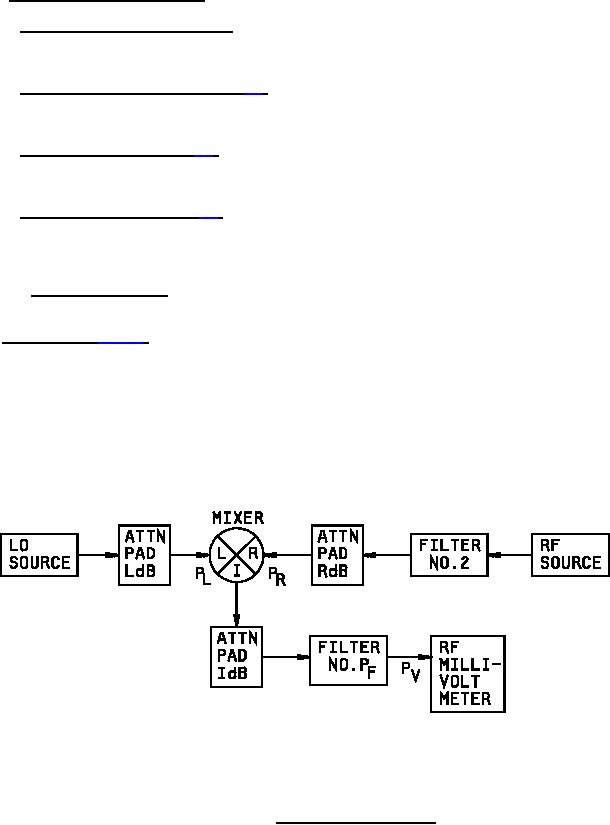

requested. Unless otherwise specified (see 3.1), LO input level shall be +7 dBm. "Equivalent" test setups may be

used provided they are industry accepted as equal to or better than the setups shown in figures 1 through 9.

4.7.4.1 Conversion loss (SSB). The conversion loss of mixers shall be measured at the low end and high end of

the specified frequency range (see 3.1).

Procedure (see figure 1). The RF input level shall be -10 dBm and the LO input shall be as specified (see 3.1

and 4.7.4). When the -10 dBm input is such to cause a given mixer to operate in its nonlinear range, the RF

input level shall be adjusted so the mixer shall operate in its linear range. The characteristic of the crystal filter

number 1 shall be such that it will reject all responses other than the desired or specified intermediate frequency

(IF). The characteristic of the filter number 2 shall be such that it will attenuate all harmonics of the RF source

by at least 30 dB.

Conversion loss = (PR - IdB - Pf - PV) dB

FIGURE 1. Conversion loss test setup.

12

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business