MIL-DTL-28837C

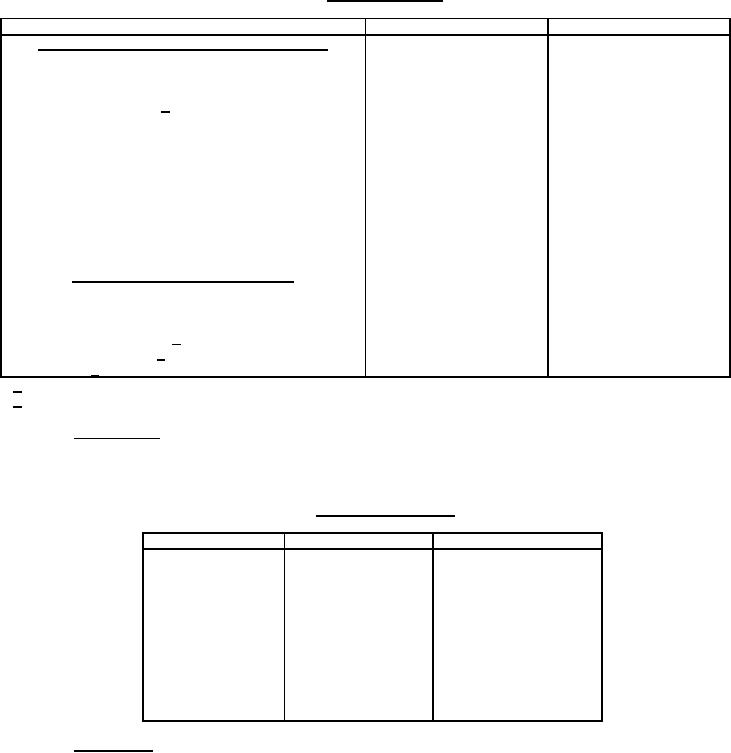

TABLE III. Group A inspection.

Inspection

Requirement paragraph

Test method paragraph

Subgroup I (screened and unscreened samples)

Visual and mechanical examination------------------------------

Seal ---------------------------------------------------------------------

Electrical characteristics 1/ ----------------------------------------

Conversion loss -----------------------------------------------------

---

Noise figure ----------------------------------------------------------

---

Isolation ---------------------------------------------------------------

---

Conversion compression -----------------------------------------

---

Conversion desensitization --------------------------------------

---

Intermodulation------------------------------------------------------

---

Insertion loss---------------------------------------------------------

---

VSWR -----------------------------------------------------------------

---

RF leakage -----------------------------------------------------------

---

Subgroup 2 (screened samples only)

Thermal shock ---------------------------------------------------------

3.8

Vibration -----------------------------------------------------------------

Seal ----------------------------------------------------------------------

Electrical characteristics 1/ --------------------------------------

Radiographic inspection 2/------------------------------------------

Acceleration 2/--------------------------------------------------------

1/ As applicable (see 3.1).

2/ Additional screening requirement for space flight mixers.

4.6.1.2.1 Sampling plan. Statistical sampling and inspection shall be performed on an inspection lot basis with a

random sample of mixers selected in accordance with table IV. Acceptance levels shall be based upon the zero

defective sampling plan. No failures shall be permitted.

TABLE IV. Group A sampling plan.

Lot size

Sample size

Space flight mixers

1-

13

100 percent

100 percent

14 -

150

13

100 percent

151 -

280

20

100 percent

281 -

500

29

100 percent

501 - 1,200

34

100 percent

1,201 - 3,200

42

100 percent

3,201 - 10,000

50

100 percent

10,001 - 35,000

60

100 percent

35,001 - 150,000

74

100 percent

150,001 - 500,000

90

100 percent

500,001 and over

102

100 percent

4.6.1.2.2 Rejected lots. If an inspection lot is rejected, the contractor may rework it to correct the defects, or

screen out the defective units, and resubmit for reinspection. Resubmitted lots shall be inspected using tightened

inspection, defined as double original sample size with acceptance on zero failures. If tightened inspection fails, the

rejected lot shall not be re-inspected, re-screened, or reworked. All rework shall be performed prior to re-inspection.

Resubmitted lots shall be separate from new lots, and shall be clearly identified as reinspected lots.

10

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business